Industry 4.0

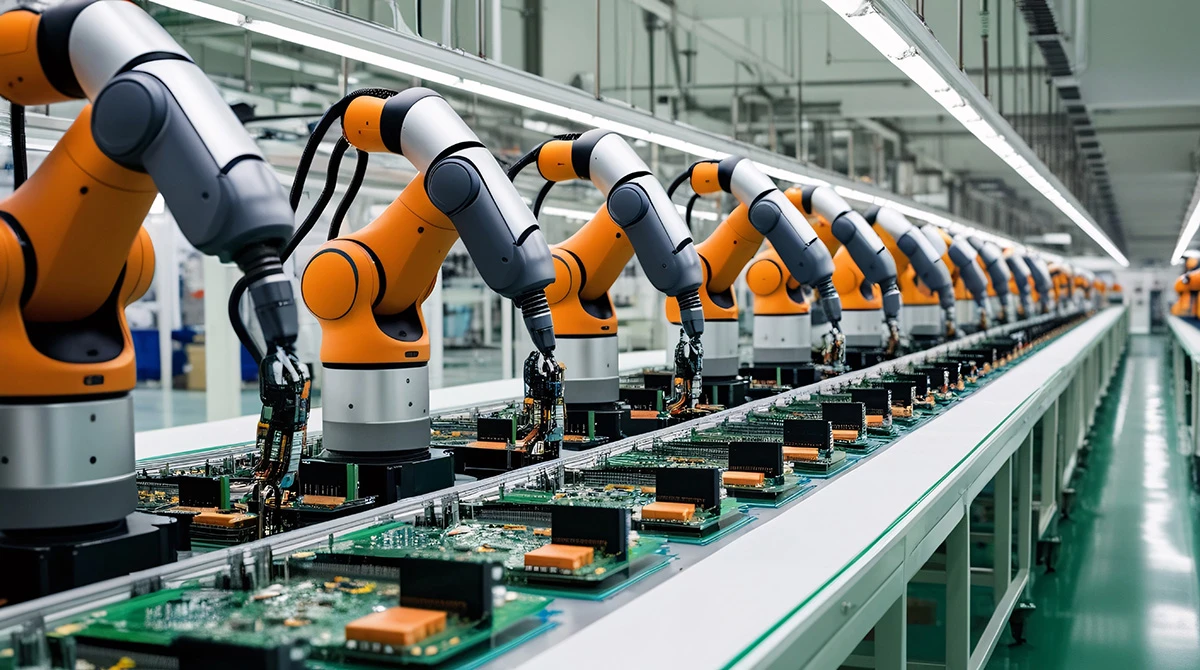

The CERTI Foundation drives digital transformation in industry through the design, development and implementation of intelligent processes and integrated information and communication technology systems. Using advanced production practices aligned with Industry 4.0 concepts, such as PIMS (Plant Information Management System), CERTI offers customized, flexible and automated solutions for the integration of technological products.

These solutions, which can be replicated in any manufacturing environment and are duly tested, aim to reduce costs, increase quality and control production.

READ ON THE BLOG

Learn about some of CERTI’s services or products that have Industry 4.0 as their main competence:

Complete projects for new factories: from feasibility studies and conceptual design to the complete executive project, including implementation and monitoring of works.

Integrated process development: for new products and electronic products, accelerating their introduction to the market and reducing the “Time to Market”.

Optimization of existing processes: through advanced analysis tools and process development methodologies, focusing on productivity, capacity, reliability and cost reduction indicators.

Factory floor management systems (PIMS): improving production control and monitoring with online and real-time monitoring, production and quality indicators, and complete product traceability records.

Visual management of the factory floor: systems for real-time collection of information, allowing the visualization of production status, indicators and dashboards.

Systems for product traceability and integration: customized software for traceability, computerized assembly instructions and application of identification and location technologies.

Development of supervisory systems: SCADA systems for monitoring and controlling industrial processes, with communication in different protocols, historical records, alarms and graphical interfaces.

Quality planning, assurance and evaluation: Offers complete solutions in quality assurance, from initial planning to continuous improvement of products and processes. We operate in all stages, from the development of new products and the analysis of specifications to the performance of rigorous tests and the implementation of continuous improvements. Our tools include failure mode and effects analysis (DFMEA/PFMEA), reliability and thermal performance testing, and conformity analysis, ensuring that your products meet the highest quality standards.

OpenBIM

CASES

Meet our Factory Laboratory:

Let's

Talk!

Contact us and let’s talk about how CERTI can contribute to your development!